MAKE IT HAPPEN WITH OUR

Industrial

Services

We specialize in services such as Inspection, Wet and Dry Tumbling, Magnetic Particle Inspection, Ultrasonic Cleaning, and Electronic Components.

Do you have a special need? Arete can develop a process to meet your non-standard type work.

Inspection and Packing Services

At Arete QIS, we provide top-notch inspection and packaging services for your industrial needs. You can expect excellent customer service and quality workmanship when you choose us. We are an ISO certified business. Call us today for more information.

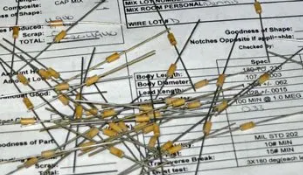

Sorting and Inspecting Cababilities

We are capable of separating mixed or non-conforming parts by a visual and/or gauging process. Call us at (814) 781-1194 to request an estimate or fill out our online form.

Light Assembly Work

Our capabilities range from simple assembly of mechanical parts to more complex electronic assemblies.

Hand Packing

From packing in customized customer dunnage to layer packing in cardboard boxes and ship them to you or directly to your customer.

Dedicated Service You Can Count On

Do you have a special need? Arete can develop a process to meet your non-standard type work. We have met special needs such as hand de-burring of parts and container (returnable dunnage) rework and cleaning.

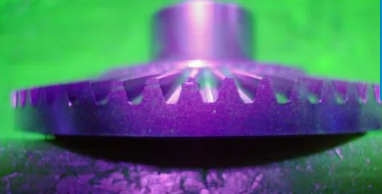

We currently have 14 cubic ft., 12 cubic ft., and 3 cubic ft. vibratory tumblers for large and small requirements.

With our large variety of tumbling media and chemistry, we are able to meet most of your tumbling needs. Our in-line separator and drying furnace assure a quality product. To add shelf life to your items, we can apply a rust inhibitor.

No tumbling job is too big or too small when you come to Arete QIS. Depend on our local, family-owned business with over 20 years of experience for all your tumbling needs. Call (814) 781-1194 today for details.

Fully Certified, Customer-Based Service for Your Convenience

Arete QIS is a leading ISO 9001:2015 certified industrial solution provider. Our company was formed with you in mind. From sorting, inspection and packaging to special needs, we make manufacturing amazingly safe and simple all over the world.

Get in touch with us today for a FREE quote

Trusted Wet and Dry Tumbling Mechanisms

Professional Grit Blasting

Grit Blasting: Our 3 cubic foot Wheelabrator is capable of running a variety of parts and surface finishes in a timely manner with competitive pricing.

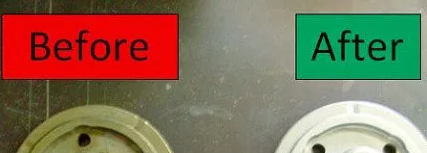

Our abrasive blasting process can remove scale and/or rust or just change the finish on a part. We can prep the surface for coatings and paintings by propelling shot media under pressure to clean, smooth or change the finish on your parts. Fill out our form to request an estimate or call (814) 781-1194.

Magnetic Particle Inspection: MPI

Magnetic Particle Inspections

Magnetic particle inspection (MPI) is a form of non-destructive testing that uses magnetism and specially designed particles to detect indications of cracks. Compared to some other methods of non-destructive testing, MPI is a faster and more efficient method of testing for cracks. Arete uses the wet-fluorescent method of MPI with fluorescent particles and black light inspection.

Here at Arete, our machines are capable of single and multidirectional shots to provide the most specific inspections required. Our machines are able to run as AC or DC to detect surface and sub-surface indications. We offer both water and oil solutions to suit the needs of our customers. The particles used in the water and oil baths vary in size to provide the best possible results for a range of crack widths. Our water solution contains a liquid concentrate that includes a rust inhibitor to protect parts with no additional processes required. No rust preventative steps need to be taken with our oil bath.

Arete has two inspection rooms equipped with overhead black lights for optimum inspection. After sorting, all parts are demagnetized according to specific requirements. From here, the options are open to customer needs. Parts can be packed directly at the MPI area or sent to our sorting department for special packaging or further inspection.

The operators in our MPI department have specific training for MPI. All inspectors are certified at a minimum of Level I-Limited before being trained on inspection. Training courses are held intermittently for Level I and Level II technician certification according to SNT-TC-1A and NAS-410. These courses are conducted by our Level III consultant. Our MPI department is overseen by a supervising Level II technician.

The quality and procedures of our MPI department are handled by Georgia Cornell, a Level II consultant. Georgia has worked at Arete since June 2010 and was certified a Level II technician in October 2010. In December 2011, she began handling MPI quality matters and procedure set-ups and overseeing the training and evaluations of MPI operators. In addition to MPI, she is currently studying other NDT methods in order to obtain a Level III certification.

Reliable Detection of Surface and Sub-Surface Indications

Our semi-automated MPI units are capable of single- and multi-directional shots to detect surface and sub-surface indications. To meet your requirements, we have water and oil mediums available and use black light inspection.

Magnetic particle inspection is a great method of crack detection. After a part is magnetized, fine iron particles coated with a dye pigment, bridge or arc the crack. This helps us detect if there is a problem with your shipment.

Call Arete QIS today with your MPI inquiries today. Same-day services are available for an additional fee. You can also request an estimate by filling out our short form.

Comprehensive Services, Reliable Results

Did you know that Arete QIS is a leading ISO 9001:2015 certified industrial solution provider? Our company was formed with the idea of meeting all of your sorting, inspection, packaging, and special manufacturing needs. We provide innovative services throughout the USA and Europe.

Call (814) 781-1194 and let us know how we can assist you.

Innovative Ultrasonic Cleaning

Ultrasonic Cleaning Is a method that uses ultrasound and chemistry to clean. It thoroughly removes tightly adhering or embedded particles from all types of surfaces, and uses water and/or mild solvent with rust preventative added for cleaning medium.

We have two systems to meet your large and small orders. Depend on ultrasonic cleaning to thoroughly remove stubborn particles from your solid surfaces.

Find the Cleaning Services You Need, All in One Place

Our process can clean a wide range of your work piece shapes and sizes like engine parts, jewelry, firearms, electronics, optics, textiles, and all types of ferrous and non-ferrous metals including Powdered Metal. Our process may not require the part to be disassembled prior to cleaning.

We have 2 systems to meet large and small orders. Call (814) 781-1194 for a free estimate on your ultrasonic cleaning needs

We Only Use High Quality Materials

When you opt for ultrasonic cleaning, you should know that we use water and/or mild solvents with rust preventative chemistry to protect the integrity of your parts. Also, our process may or may not require the part to be disassembled prior to cleaning.

Fill out our short form to request an estimate.

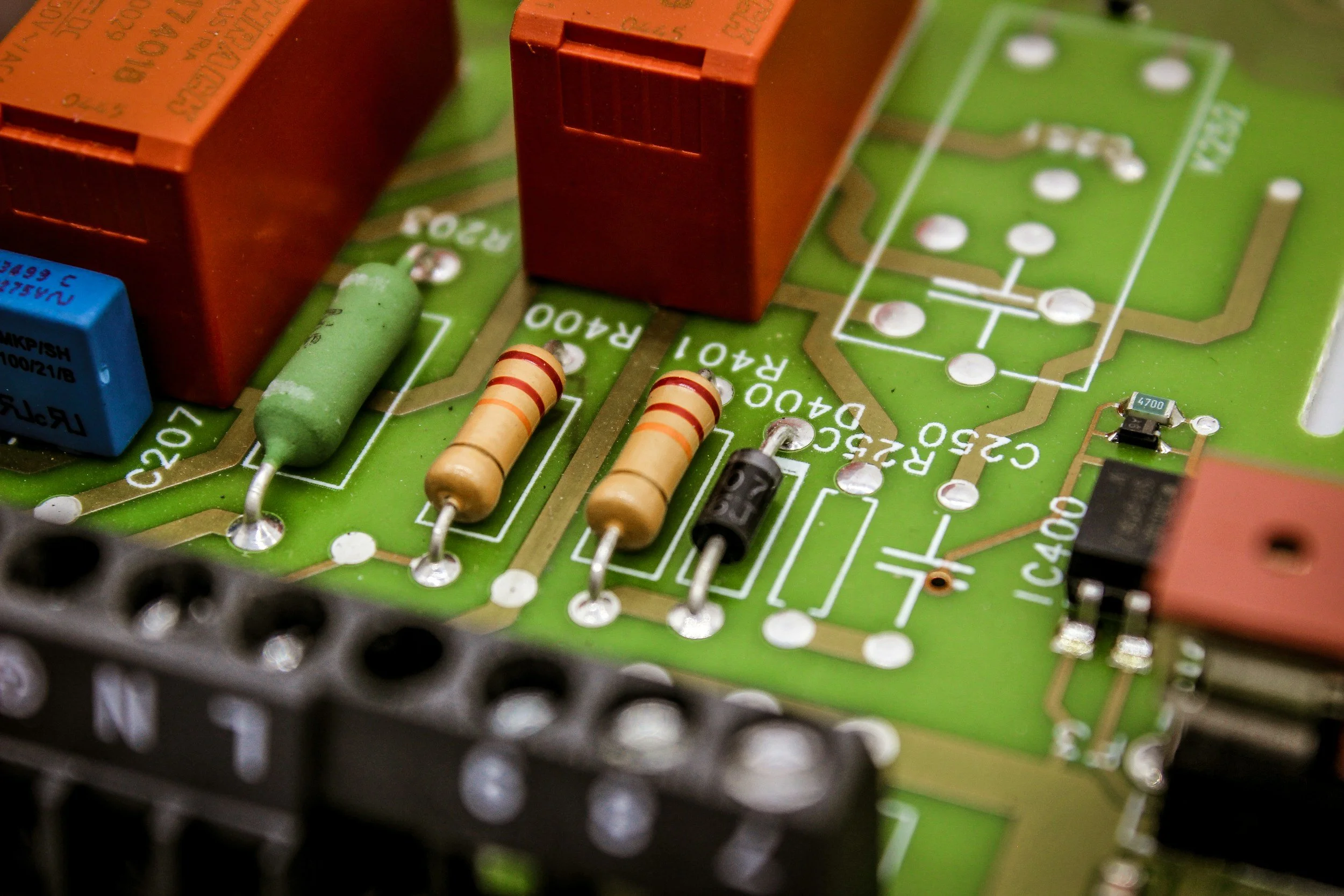

Providing You With Reliable Electronic Elements

QCI was founded in 1950 as a global manufacturer of passive electronic components. Our company is still at the original 55,000 sq. ft. location and is fully capable of producing a high-quality product at reasonable prices you can afford.

Arete's product line includes iron powder and phenolic axial–leaded winding forms (coil forms and bobbins), iron powder sleeves, and circuit jumpers. Our products serve the automotive, avionics, communications, computer, consumer electronics medical, and telecommunications industries. Call Arete QIS today for an estimate. We'll provide you with an estimate within 24 hours. You can also fill out our form to request an estimate.

Benefit From Short Lead Times on All Orders

Whether you have a very large custom order or something a tad smaller, your products will be handled in the same professional, prompt manner. Know that you are our top priority and we will do all that we can to give you great results.

Learn More About Our Products:

Molded coil forms: Available in a wide range of sizes designed to meet your PCB needs, our winding forms manufactured to the closest electrical and mechanical specs in the industry with standard 100% tin plated oxygen free copper leads. We also offer Type C-32-N, 60/40 plated, oxygen-free copper leads to eliminate the need for a solder dip process.

Capacitors: Our capacitors with 100% tin-plated, oxygen-free “molded in leads” that meet RoHS directive from the European Parliament. For your high-reliability requirements, our broad range of low value, close tolerance capacitors can be engineered to meet demanding needs. All of our QIS capacitors are available in balk or on tape and reel packaging for automatic PCB insertion.

Bobbins: Our bobbins are supplied in powdered iron or phenolic material with “molded in leads.” They are tailored to meet requirements of limited board space. Our mechanically rugged bobbins are manufactured with parallel slots for wire anchorage.

Circuit jumpers: Our circuit jumpers are used to interconnect various circuits on printed boards consisting of 22 A.W.G. tinned copper wire with a thermoset plastic shell that is 0.25 inches (6.35mm) long molded over the central portion. Our circuit jumpers are manufactured with uniform dimensions allowing them to be used with the same automatic inserting machinery as other components assembled onto a circuit board. We can supply these parts in bulk packaging, lead taped, or reel packed.

Sleeves: Our sleeves will meet all of your shielded coil requirements and are available in a broad range of sizes. To reduce magnetic coupling between components, our uniquely manufactured sleeves are processed to precise T.I.R. specifications, along with tightly held electrical parameters.